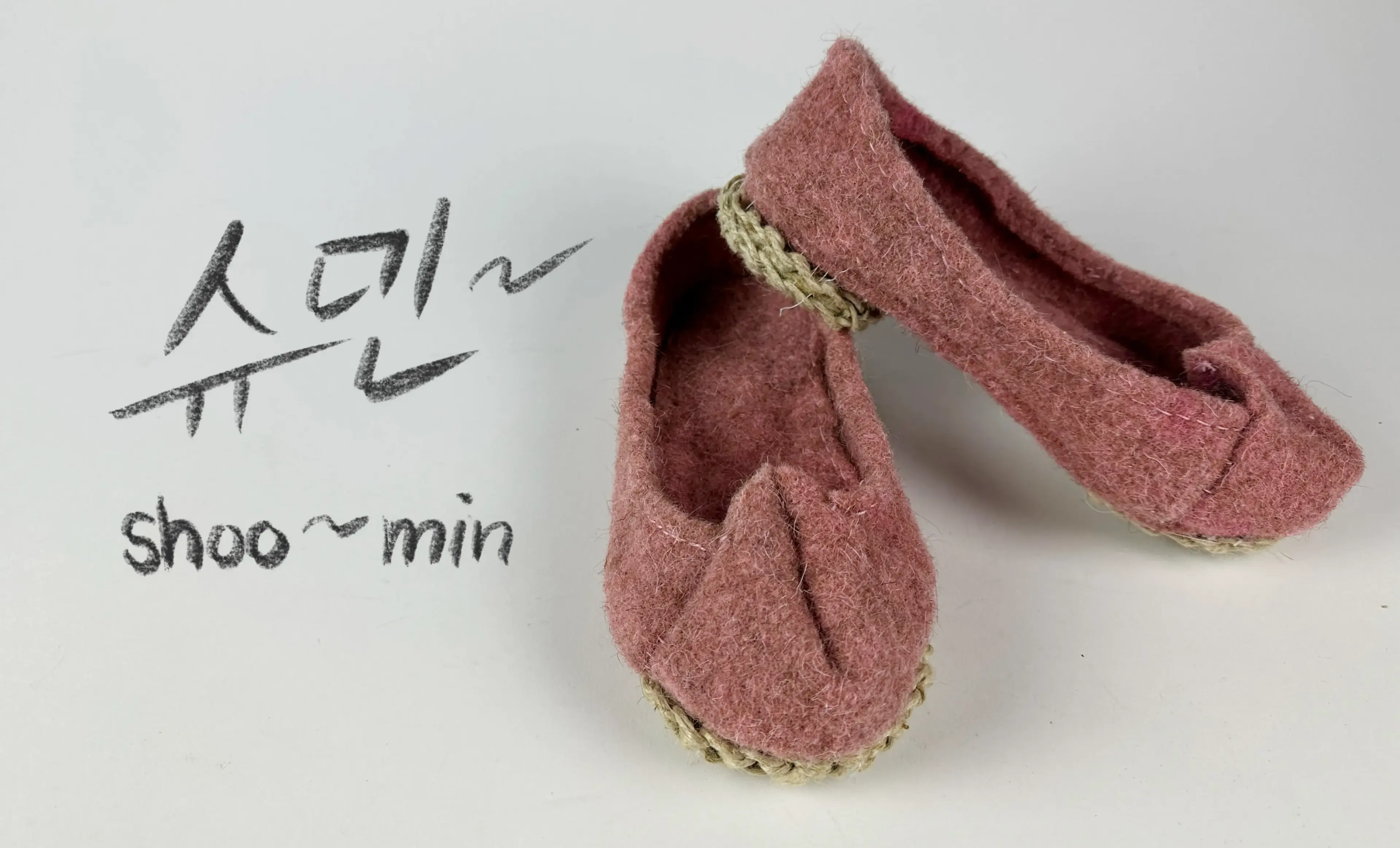

Shoo~Min

A Korean tradition-inspired sustainable shoe

Timeline

6.5 weeks

January 2024 - March 2024

My role

Designer/Prototyper

Team

Just me!

Tools

Sewing

Pattern Making

3D Scanning

The Project

Design a fully sustainable pair of wearable shoes using only the provided wool felt and an eco-friendly sole material. The footwear had to demonstrate proper fit, comfort, durability, and aesthetic quality.

The Problem

How might I design a soft, sustainable everyday shoe that blends comfort, form, and cultural reference into a single felt construction?

The Solution

Shoo~min is a soft everyday flat designed and constructed from a single sheet of eco-felt with a crocheted sole, blending sustainable materials with inspiration from traditional Korean footwear.

The Inspiration

I drew inspiration from traditional Korean footwear combining the gomusin’s simple, curved slip-on form with the jipsin’s natural, sustainable material. This direction allowed me to merge cultural heritage with eco-conscious soft-goods design.

The Material

A single sheet of natural wool eco-felt served as the core material for this project.

Why Eco Felt?

- Biodegradable and renewable natural fiber

- Naturally breathable, warm, and durable

- Supports minimal-waste and eco-friendly construction

Material Properties

- Dense fiber structure allows for:

- Laser cutting with clean edges

- Folding & layering without tearing

- Stitching without fraying

- Fully dyeable, allowing color customization

- Provides a balance of softness and structural integrity

The Sole Material

I hand-crocheted the sole using hemp and mixed fibers to form a rounded, supportive base, with extra layers at the heel to improve durability.

Why Hemp Twine?

- Hemp twine was selected for its durability and sustainability, while visually referencing the woven structure of traditional Jipsin shoes.

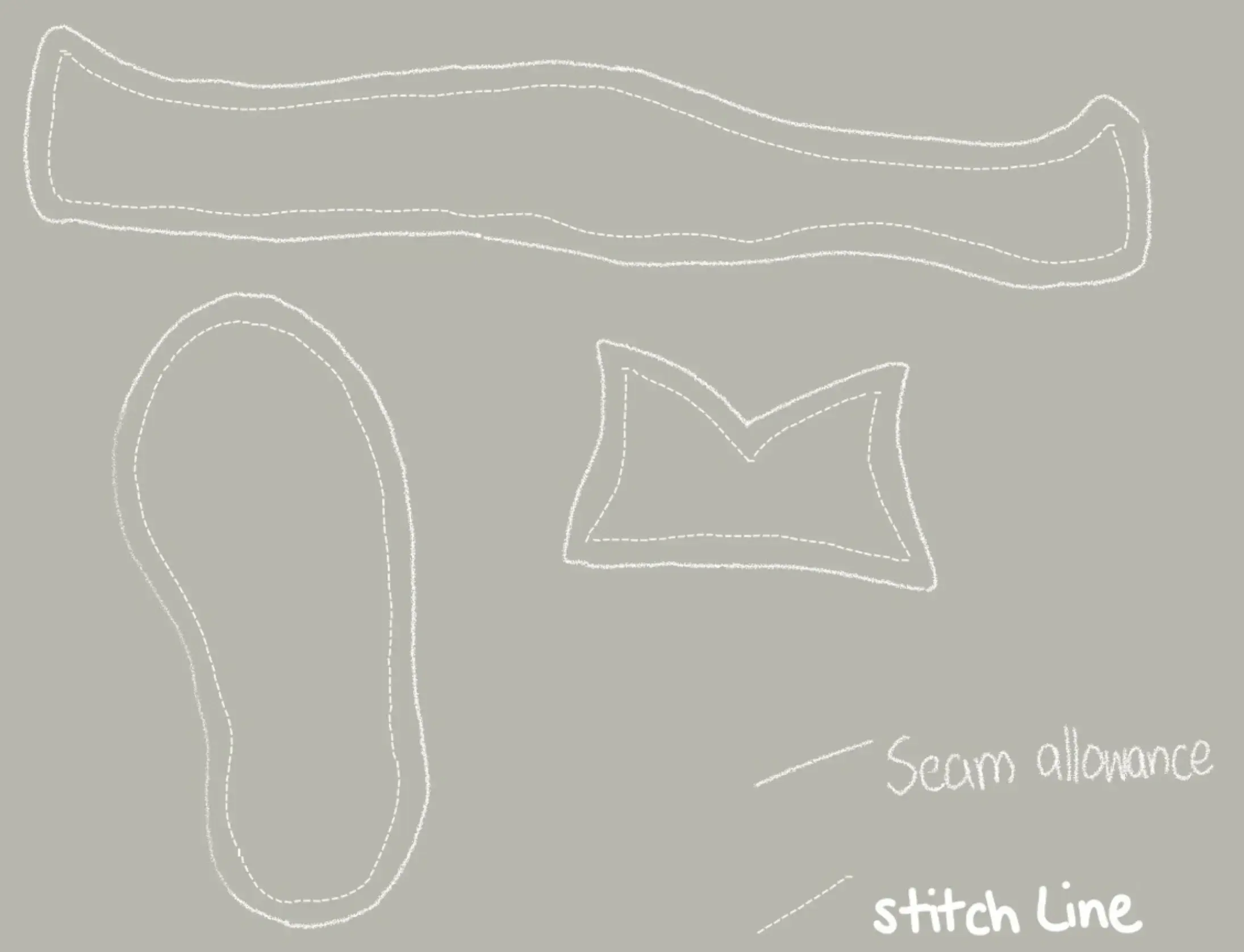

Final Pattern

- Using a seam allowance, I stitched the shoe inside-out and then flipped it right-side out so all raw edges and stitching are hidden inside the shoe for a cleaner finish.

- I added seam allowance and hemmed the top edge to create a clean, finished opening with no exposed raw felt.

Final Shoe

Motion Study